TIG/MIG Automatic Circular Seam Welding Machine with Customized Voltage

Mainly used for the barrel of the seam welding, single gun welding can be connected to the maximum length of 3000mm. Mainly by the rotary head frame, tailstock, hydraulic pump station, beams, electric carriage, arc shield, control box and other components. Welding, the workpiece at one end with the main shaft on the three-jaw adjustable chuck clamping range 50 ~ 300mm, according to the scale on the grip plate scale to ensure that the workpiece cylindrical and spindle concentric. The other end of the hydraulic tailstock on the alignment device on the top, and as needed in the middle of the workpiece with a liftable pneumatic bracket support.

Features:

1) The welding torch is fixed; the work piece rotating, welding position is horizontal.

2) The work piece rotation is driven by clamping, roller bearing bracket.

3) The torch is adjustable along the longitudinal beam, adaptable to various welding.

4) Machine is PLC control, the work piece rotation adopts AC servo motor speed control, stepless adjustable, improve equipment reliability.

5) The form and parameters of welding can be preset, storing and transferring. Through touch screen human-machine interface can easily change the parameter and state transition.

6) The torch can be adjusted up and down, left and right, dip angle, in order to meet the welding requirements.

Applications:

Automatic Circular Seam Welding Machine. To ensure concentricity, uniform forming, good appearance, weld penetration and weld width meet the technological requirements, the clamping is convenient. MIG/MAG welding process, complete in one time welding.

Applicable to carbon steel, stainless steel, titanium alloy, aluminum alloy welding materials;

Suitable for all types of parts of the ring joints docking, angle and other structural forms;

Suitable for TIG, MIG / MAG, PAW and other welding process;

Technical Parameters:

| Model |

HFW-1000 |

HFW-1500 |

HFW-2000 |

HFW-2500 |

HFW-3000 |

| Welding length (mm) |

≤1000 |

≤1500 |

≤2000 |

≤2500 |

≤3000 |

| Min. cylinder diameter (mm) |

φ30-φ300 |

φ50-φ400 |

φ100-φ500 |

φ150-φ800 |

φ200-φ1000 |

| Rotation speed (rpm) |

0.125-2.5 |

0.075-1.5 |

0.075-1.5 |

0.05-1 |

0.05-1 |

| Speed control |

Various Frequency Drive |

| Work piece clamp method |

Pneumatic |

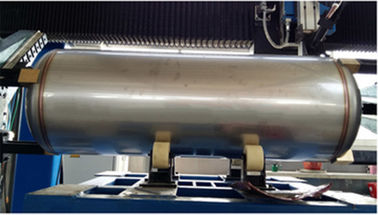

Welding Samples:

FAQ:

When the machine can't work well, what should I do?

1. Engineer is online for 24-hours, they can check the problems and then give you solutions in two hours.

2. Our machine is with one year's warranty. If any problems of machine parts under "normal use", new machine parts will be sent by air in free.

3. Please rest assured that operation CD and manual will be offered along with machine, making you can operate the machine easily.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!