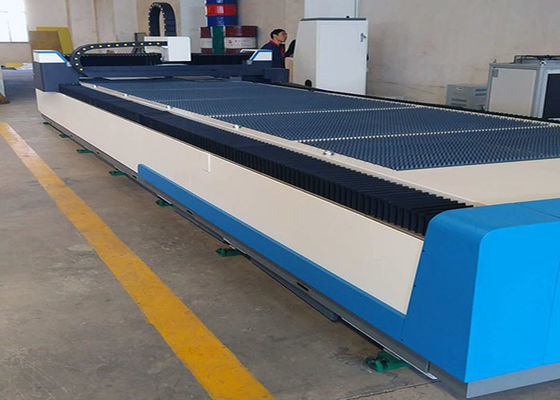

High Efficiency CNC Laser Cutting Machine 3000W 1500X6000mm

Industrial-Grade High Efficiency CNC Fiber Laser Cutter | 3000W 1500×6000mm Large Format

Introducing the High Efficiency CNC Laser Cutting Machine with 3000W power and 1500×6000mm extra-large working table—your ultimate solution for large-scale, high-demand metal processing tasks. Engineered for industrial production scenarios, this laser cutter combines robust power output, extended processing area, and intelligent operation systems to redefine efficiency and precision in metal fabrication. Whether tackling long-length metal sheets for construction, bulk production of automotive components, or customized large-format metal artworks, this machine delivers consistent performance while minimizing production cycles and operational costs.

As a breakthrough in heavy-duty laser cutting technology, this 3000W CNC laser machine integrates high-performance fiber laser modules, reinforced mechanical frameworks, and advanced motion control systems. It excels in cutting a wide spectrum of metal materials with greater thickness, outperforming standard models in both productivity and versatility. Designed to cater to the evolving needs of large manufacturing plants, engineering firms, and professional processing workshops, this high-efficiency laser cutter is set to become a core asset for businesses aiming to scale operations and gain a competitive edge in the global market.

Product Structure:

Core Advantages & Performance Highlights:

3000W High-Power Laser Source: Adopts top-tier fiber laser source (selectable from IPG, Raycus, Maxphotonics) with electro-optical conversion efficiency up to 32%, ensuring strong and stable laser energy output. Enables efficient cutting of thick metal sheets—ideal for heavy-industry applications that demand high penetration and fast processing speeds. Boasts a service life exceeding 120,000 hours, significantly reducing downtime and replacement costs.

1500×6000mm Extra-Large Working Table: Features an elongated working area specifically designed for processing long-length metal sheets (e.g., 6-meter steel plates). Eliminates the need for frequent material splicing and repositioning, greatly enhancing production efficiency for large-format products like steel structures, shipbuilding parts, and long-span architectural components. The table is equipped with a high-load-bearing roller system, supporting a maximum load of 1500kg for stable processing of heavy workpieces.

Enhanced Cutting Efficiency & Precision: Integrates high-precision linear guide rails with double drive motors, achieving a positioning accuracy of ±0.025mm/m and repeat positioning accuracy of ±0.015mm. The maximum cutting speed reaches 40m/min for thin carbon steel, 30% faster than conventional 3000W models. Equipped with adaptive cutting technology that automatically adjusts laser power and cutting speed based on material thickness, ensuring smooth edges and consistent cutting quality across the entire working area.

Robust & Durable Mechanical Structure: The machine frame is constructed from high-strength welded steel with integral stress relief treatment, effectively resisting deformation even under long-term heavy-load operation. The gantry-style design with reinforced beams enhances structural rigidity, minimizing vibration during high-speed cutting and ensuring stable performance. The enclosed protective cover not only safeguards operators but also prevents dust and debris from affecting internal components.

Intelligent & User-Friendly Operation: Equipped with the latest generation CNC control system (optional: CypCut Pro, FSCUT 4000), featuring a 15-inch touchscreen display, intuitive interface, and full-featured offline programming software. Supports automatic nesting, material edge detection, and real-time cutting monitoring, reducing operator training time and human errors. The system is compatible with multiple file formats (DXF, PLT, AI) and allows for remote fault diagnosis and software updates.

Advanced Dust & Smoke Extraction System: Equipped with a dual-channel exhaust system and high-efficiency cyclone dust collector, capturing over 95% of smoke and metal dust generated during cutting. Complies with international environmental protection standards (EPA, CE PED) to ensure a safe and clean working environment. The detachable dust collection box facilitates easy maintenance and waste disposal.

Broad Material Processing Capability: Capable of cutting various metals including carbon steel (max thickness ≤20mm), stainless steel (max thickness ≤12mm), aluminum alloy (max thickness ≤10mm), copper (max thickness ≤8mm), and other non-ferrous metals. Suitable for both ferrous and non-ferrous metal processing, eliminating the need for multiple specialized machines and expanding business service scope.

Energy-Saving & Low Maintenance Design: Incorporates intelligent power management technology that automatically adjusts energy consumption based on working status, reducing total power consumption to ≤9kW. Fiber laser technology eliminates the need for laser gas and reduces wearing parts, with maintenance intervals extended to 6 months—lowering long-term operational costs by up to 40% compared to traditional CO2 laser cutters.

Main Components:

Technical Specifications:

| Technical Parameter |

Parameter Value |

| Model |

FL-6015-3000W |

| Laser Type |

Pulsed/Continuous Wave Fiber Laser |

| Laser Power |

3000W (Optional: 2000W, 4000W, 6000W) |

| Working Area |

1500mm × 6000mm |

| Positioning Accuracy |

±0.025mm/m |

| Repeat Positioning Accuracy |

±0.015mm |

| Max Cutting Speed |

40m/min (for 1mm carbon steel) |

| Max Cutting Thickness (Carbon Steel) |

≤20mm |

| Max Cutting Thickness (Stainless Steel) |

≤12mm |

| Max Cutting Thickness (Aluminum Alloy) |

≤10mm |

| Max Cutting Thickness (Copper) |

≤8mm |

| Laser Wavelength |

1060-1080nm |

| CNC Control System |

CypCut Pro / FSCUT 4000 (Optional) |

| Cooling System |

Industrial Water Chiller (Temperature Control Precision: ±0.3℃) |

| Power Supply |

AC 380V/50Hz/3Phase (Customizable: 415V/60Hz) |

| Total Power Consumption |

≤9kW |

| Machine Dimension (L×W×H) |

8200mm × 2600mm × 2000mm |

| Machine Weight |

6500kg |

| Table Loading Capacity |

1500kg |

| Operating Environment |

Temperature: 10℃ - 40℃; Humidity: ≤75%; No Strong Vibration or Magnetic Interference |

Cutting Samples:

Questions:

1. Are you a trading company or factory?

--- We are factory occupying more than 100,000 m2, with excellent and professional technical team, 25 R&D personnel, professional after-sales team, and around 200 workers producing more than 1000 sets machines each year.

2. Does your company supply and build the machines to suit customer's needs and specifications?

--- Yes, we can custom-made the machine according to your requirements.

3. What is your advantages over your competitors' machine?

--- Our machines can be equipped with high configuration, and main components are from famous brands. We have strict quality control system, process technology system, technology innovate system.

4. Does the machine come with a guarantee?

--- We offer one year of warranty, during this time, if any parts broken, we will send a new one to customer free of charge, and we will also supply on-line the technical guidance for ever free.

5. Can I go to visit your factory?

--- Welcome to visit our factory to know our processing and technology power. And you will see different sample machine at our workshop.

6. How to get quicker quotation?

--- When you send us inquiry, please offer your requirement information:

• What kind of metal plate and the thickness?

• What’s the size of your workpiece?

These information is helpful for us to choose suitable equipment solution and price quickly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!