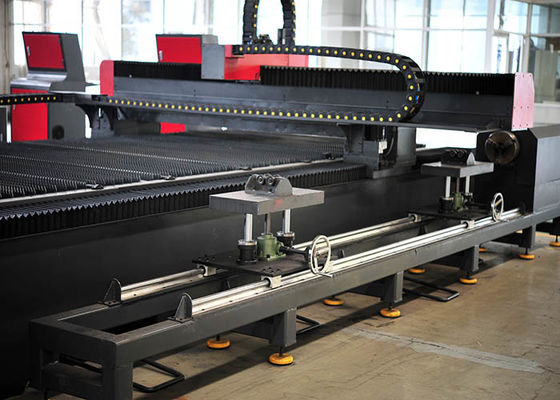

3KW-45KW Dual-Purpose Fiber Laser Cutter for Tube & Plate Processing

Product Overview:

Our 3KW-45KW Dual-Purpose Fiber Laser Cutter for Tube & Plate Processing is a cutting-edge, integrated metal processing equipment tailored for the high-efficiency, high-precision production demands of modern manufacturing. By integrating optimized tube cutting and plate cutting functions into one compact unit, this machine breaks the limitations of single-function cutting equipment, enabling manufacturers to handle mixed production tasks of different workpieces with a single device, thereby streamlining production processes, lowering equipment investment costs, and enhancing overall workshop operational efficiency.

Equipped with a high-stability fiber laser source and an intelligent digital control system, it boasts excellent adaptability to various metal materials, covering carbon steel, stainless steel, aluminum alloy, copper, and special alloy materials, and can efficiently process workpieces from ultra-thin sheets to extra-thick plates. It is widely applicable to multiple key industries: in the automotive manufacturing industry, it handles precision cutting of small and medium-sized plate components such as car body frames and engine parts; in construction steel structure processing, it undertakes large-format plate cutting for steel beams, columns and curtain wall components; in the hardware and furniture industry, it realizes complex contour cutting of various tubular workpieces like handrails and brackets; in aerospace, it processes high-precision thin-walled plate parts; in precision hardware, it cuts small-sized high-precision components; and in architectural decoration, it completes personalized cutting of decorative metal plates and tubes. This dual-purpose laser cutter can deliver consistent cutting quality, reliable performance, and fast processing speed, making it a core production equipment for these industries.

Features:

• Dual-Purpose Integrated Design for Tube & Plate: Adopts a modular integrated structure, realizing quick switching between tube and plate cutting modes in 30 seconds without manual disassembly and adjustment. The compact design reduces equipment floor space by 40% compared with separate tube and plate cutting machines, saving workshop resources.

• High-Efficiency & Stable Laser Source: Offers a flexible power range of 3KW-45KW to match diverse cutting scenarios. Selected high-quality brand fiber laser source features ultra-high electro-optical conversion efficiency (up to 32%), which significantly reduces energy consumption during operation, and a long service life of over 120,000 hours, minimizing maintenance costs.

• Precision-Optimized Transmission System: Equipped with high-rigidity linear guides and precision ball screws with preload treatment, combined with imported high-performance servo drives, achieving positioning accuracy of ±0.02mm/m and repeat positioning accuracy of ±0.01mm. The machine bed is subjected to high-temperature aging treatment and finite element optimization design, ensuring strong stability during high-speed and heavy-load cutting without deformation.

• Intelligent High-Speed Cutting: Integrates advanced dynamic focusing laser cutting technology, with a maximum cutting speed of up to 70m/min for 1mm carbon steel, which is 3-4 times that of traditional plasma cutting. Equipped with self-developed intelligent nesting software that supports automatic material layout optimization and leftover material reuse, improving material utilization rate by up to 15%.

• Wide-Range & Reliable Tube Cutting: Supports cutting of round tubes, square tubes, rectangular tubes, elliptical tubes, and special-shaped tubes with a diameter range of φ15-φ350mm and wall thickness up to 25mm (adjustable according to power). The upgraded hydraulic clamping system with multi-point positioning ensures firm clamping of workpieces and avoids deformation during cutting, ensuring cutting precision of tube ports.

• Humanized Intelligent Control: Adopts a 15-inch touchscreen industrial CNC control system with a visualized operation interface, which is simple and easy to learn, reducing the threshold for operator training. Supports offline programming, remote monitoring, and fault self-diagnosis functions, enabling real-time grasp of equipment operation status and timely handling of faults, improving production management efficiency.

• Multi-Layer Comprehensive Safety Protection: Configures a full-enclosed protective cover with explosion-proof glass, safety light curtains, and emergency stop buttons. The laser system meets international safety class 1 standard, and is equipped with automatic laser power-off protection when abnormal conditions occur, fully ensuring the safety of operators and workshop environment.

Main Components:

Technical Parameters:

| Parameter Item |

Specification |

| Laser Power |

3KW, 4KW, 6KW, 8KW, 10KW, 12KW, 15KW, 20KW, 30KW, 40KW, 45KW (optional) |

| Laser Type |

Continuous Wave Fiber Laser |

| Wavelength |

1064nm |

| Cutting Material |

Carbon steel, stainless steel, aluminum alloy, brass, copper, special alloy, etc. |

| Plate Cutting Size |

Standard: 3000×1500mm, 4000×2000mm, 6000×2500mm; Customizable according to requirements |

| Max. Plate Thickness (Carbon Steel) |

3KW: ≤18mm; 4KW: ≤22mm; 6KW: ≤28mm; 8KW: ≤35mm; 10KW: ≤40mm; 12KW: ≤45mm; 15KW: ≤50mm; 20KW: ≤55mm; 30KW: ≤65mm; 40KW: ≤75mm; 45KW: ≤90mm |

| Max. Plate Thickness (Stainless Steel) |

3KW: ≤10mm; 4KW: ≤16mm; 6KW: ≤22mm; 8KW: ≤28mm; 10KW: ≤32mm; 12KW: ≤38mm; 15KW: ≤45mm; 20KW: ≤50mm; 30KW: ≤55mm; 40KW: ≤65mm; 45KW: ≤70mm |

| Tube Cutting Range |

Round tube: φ15-φ350mm; Square tube: 15×15-250×250mm; Rectangular tube: 15×30-250×350mm; Wall thickness: ≤25mm (depending on power) |

| Positioning Accuracy |

±0.02mm/m |

| Repeat Positioning Accuracy |

±0.01mm |

| Max. Cutting Speed (Carbon Steel 1mm) |

Up to 70m/min |

| Drive System |

High-precision servo drive system (Siemens/Yaskawa/Fanuc optional) |

| Control System |

Industrial CNC Control System (FSCut/Hypertherm/CypCut optional) |

| Cooling System |

Intelligent industrial water chiller with temperature control accuracy ±0.3℃ |

| Power Supply |

AC 380V/50Hz/3Phase (Customizable for different regions) |

| Overall Dimensions (L×W×H) |

Depends on plate size, e.g., 4000×2000mm plate model: approx. 6800×3800×2300mm |

| Weight |

Depends on power and plate size, e.g., 4000×2000mm plate, 6KW model: approx. 8500kg |

Cutting Samples:

Application Industry:

Automotive Manufacturing (body parts, engine components), Construction Steel Structure (steel beams, columns, curtain walls), Aerospace (precision thin-walled parts), Precision Hardware (small high-precision components), Architectural Decoration (decorative metal plates/tubes), Hardware Furniture (handrails, brackets), Shipbuilding (hull structural parts), Electrical Equipment (sheet metal enclosures), etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!