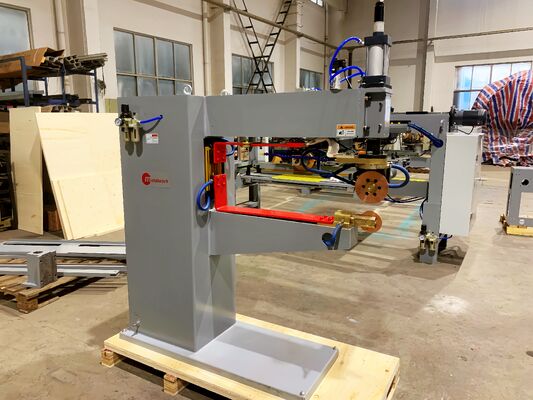

FN Series Resistance Longitudinal Seam Welding Machine

The FN Series Resistance Longitudinal Seam Welding Machine is a specialized industrial welder engineered for producing high-strength, continuous straight-line seams with exceptional consistency. Available in power ratings from 35KVA to 160KVA, this straight seam welding machine is designed for fabricating longitudinal joints in cylinders, ducts, panels, and structural sections. Ideal for manufacturing ventilation ducts, hydraulic cylinders, square tubing, and panel assemblies, the FN Series combines robust mechanical construction with precise linear tracking to deliver reliable, high-quality straight-line welds in demanding production environments.

Product Overview:

The FN Series Straight-Line Seam Welder operates on the principle of overlapping resistance spot welds in precise linear alignment. Two parallel welding wheels (electrodes) press the workpieces together while controlled electrical current passes through the contact area. As the workpiece feeds through the wheels or the welding head travels along a fixed path, it creates a continuous, uniform seam along the entire length. The machine features precision linear guidance systems and supports both continuous and pulsed welding modes for optimal results on various materials.

Machine Structure & Key Components:

- Heavy-Duty Welded Steel Frame with Precision Guide Rails – Ensures exceptional rigidity and maintains perfect linear alignment throughout the welding process.

- Pneumatic Pressure System with Linear Actuation – Provides consistent electrode force along the entire weld length, with adjustable pressure for different material thicknesses.

- Synchronized Welding Wheel Assembly – Dual electrode wheels maintain perfect parallel alignment for straight-line welding applications.

- Welding Transformer – Single-phase 380V input, designed for 50% duty cycle in continuous industrial operation.

- DC Motor & Linear Drive System – Features stepless speed adjustment from 0 to 3.2 m/min with integrated voltage compensation for consistent linear travel.

- KF9 Series Longitudinal Welding Controller – Specialized control unit with tactile rotary encoders and dials for precise adjustment of welding current, travel speed, pressure timing, and pulse sequences for straight-line applications.

- Solid-State SCR Contactor – Ensures reliable, maintenance-free switching of high welding currents.

- Integrated Cooling System – Protects critical components from overheating during extended operation.

- Workpiece Fixturing System – Customizable clamping and support mechanisms for maintaining perfect alignment during straight-line welding.

Key Features & Advantages:

- Specialized KF9 Linear Welding Controller – Features intuitive rotary encoders and dials specifically calibrated for straight-line seam welding parameters, ensuring precise control without complex programming.

- Precision Linear Tracking System – Maintains perfect wheel alignment and consistent pressure along the entire weld length for uniform seam quality.

- Stepless Current & Travel Speed Control – Continuous adjustment of welding current and linear travel speed allows fine-tuning for different materials and thicknesses.

- Dual Welding Modes – Supports both continuous seam welding for productivity and pulsed seam welding for heat-sensitive materials or thickness variations.

- Versatile Material Compatibility – Capable of welding carbon steel, stainless steel, galvanized steel, and aluminum alloys with thicknesses from 0.4mm up to 3.5mm+3.5mm.

- Adjustable Fixturing Systems – Accommodates various workpiece sizes and shapes for straight-line welding applications.

- High Production Efficiency – Automated straight-line welding process significantly reduces manual labor and increases throughput.

Machine Details:

Technical Parameters:

| Model | FN-35 | FN-50 | FN-75 | FN-100 | FN-125 | FN-160 |

| Rated Capacity (KVA) | 35 | 50 | 75 | 100 | 125 | 160 |

| Input Voltage | Single Phase 380V 50Hz |

| Input Current (A) | 92 | 131 | 197 | 263 | 328 | 420 |

| Output No-load Voltage (V) | 4.2 | 5 | 6.1 | 7.2 | 8 | 8.5 |

| Rated Duty Cycle | 50% |

| Max. Welding Thickness (low carbon steel) (mm) | 0.6+0.6 | 0.8+0.8 | 1.0+1.0 | 1.2+1.2 | 1.3+1.3 | 1.5+1.5 |

| Welding Speed | 0.8-3.2m/min |

| Electrode Stroke | 20mm |

| Flow of Cooling Water | 120L/h |

| Weight of Complete Machine (Kg) | 470 | 500 | 620 | 720 | 810 | 930 |

Welding Samples:

Applications:

The FN Series Seam Welding Machine is essential for industries requiring long, consistent, and leak-proof welded joints:

Automotive & Transportation: Fuel tanks, oil pans, mufflers, exhaust pipes, air intake systems, and structural components.

Container & Drum Manufacturing: Steel drums, chemical containers, fire extinguisher bodies, and pressure vessels.

Appliances: Water heater tanks, HVAC ducts, washing machine tubs, and oven cavities.

Metal Furniture & Cabinets: Filing cabinets, lockers, and storage units requiring sealed seams.

Construction & Building: Roofing, flashing, and gutter systems.

General Sheet Metal Fabrication: Any application where a continuous, strong, and sealed seam is required on carbon steel, stainless steel, or coated metals.

Why Choose the FN Series Seam Welder?

Proven Seam Quality: The combination of constant pneumatic force, stepless electrical control, and flexible welding modes produces strong, uniform, and hermetic seams.

Enhanced Reliability: The cylinder-based pressure system and robust KF9 controller significantly reduce maintenance and improve consistency over traditional cam-driven welders.

Operational Efficiency: Fast setup via intuitive controls, automated welding cycles, and high speed contribute to greater throughput.

Versatile Performance: Handles a broad range of materials and thicknesses, making it a single solution for multiple seam welding tasks.

Industrial Durability: Built to withstand continuous use in challenging workshop and factory conditions.

Whether you are producing automotive components, industrial containers, or general sheet metal assemblies, the FN Series 35–160KVA Resistance Seam Welding Machine delivers the precision, speed, and reliability needed to meet stringent quality and productivity goals.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!