FN-100II Customized Resistance Circular Seam Welding Machine for Smoke Vent Pipe & Elbow Joints

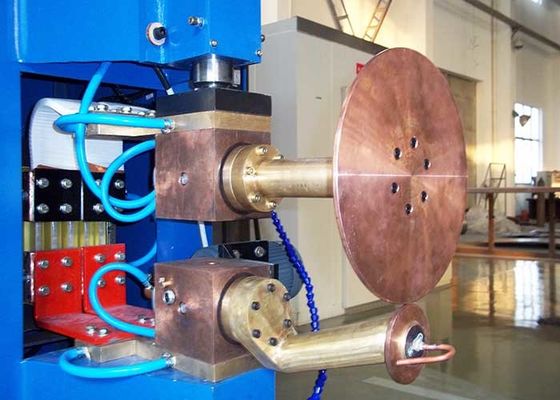

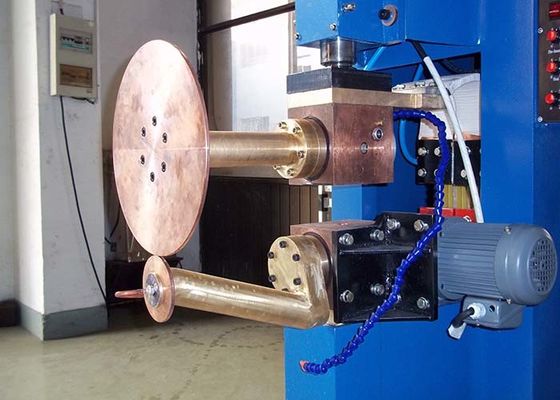

The FN-100II Customized Resistance Circular Seam Welding Machine is a specialized, application-engineered welding system designed for the precise and efficient production of smoke vent pipes and their critical elbow joints. Built upon the robust FN Series platform, this 100KVA custom seam welder is specifically tailored to weld both standard cylindrical pipes and the challenging curved "neck" sections (elbows) used in ventilation and exhaust systems. Featuring a unique curved lower electrode shaft and dual copper arm configuration with square-box current conduction, this machine delivers reliable, airtight circumferential seams on thin-walled ductwork from 0.5mm to 1.2mm in thickness.

Product Overview:

The FN-100II Custom Smoke Vent Pipe Welder addresses the specific challenge of welding both straight pipe seams and the curved seams of pipe elbows (90° or other angle bends). Unlike standard circular seam welders, this machine incorporates a specially designed curved lower copper shaft (70mm diameter wheel, 250mm length) that aligns perfectly with the internal radius of pipe elbows, enabling precise welding along the bend. For standard straight pipe seams, an additional straight copper shaft assembly (55mm wheel) is supplied. The system utilizes a robust square-box secondary current conduction system, essential for machines above 75KVA, to ensure stable, high-current delivery for consistent weld quality on thin-gauge materials.

Machine Structure & Key Components:

- Heavy-Duty Welded Steel Frame with Enhanced Rigidity – Built to handle the specific forces involved in welding curved pipe sections without deflection.

- Dual Copper Electrode Arm System with Square-Box Conduction – Features both upper and lower solid copper arms integrated into a heavy-duty square-box secondary circuit for optimal current transfer and heat dissipation at 100KVA.

- Interchangeable Lower Shaft System:

- 1)Primary Curved Copper Shaft: Specially bent to match the internal contour of pipe elbows (∮70mm wheel, 250mm length). Essential for welding the curved "neck" seam.

- 2)Secondary Straight Copper Shaft: Provided as a spare for welding standard straight pipe circumferential seams (∮55mm wheel, 250mm length).

- High-Capacity Welding Transformer (100KVA) – Three-phase 380V, 50Hz input, rated for a 50% duty cycle to support continuous production.

- KF-9 Seam Welding Controller – Robust, user-friendly control unit with tactile rotary encoders and dials, providing precise adjustment of welding current, wheel rotation speed (0.8–3.2 m/min), and pulse timing for thin-gauge materials.

- Precision Rotary Drive & Workholding System – Designed to securely hold and rotate both straight pipes (∮80–300mm diameter) and elbow sections during welding.

- Dedicated Cooling System – Efficient 120L/h water cooling circuit to manage heat in the transformer, square-box arms, and electrode wheels during extended operation.

- Pneumatic Pressure System with 20mm Electrode Stroke – Provides consistent and adjustable welding force for optimal contact on varying pipe diameters and material thicknesses.

Technical Parameters:

| Model |

FN-100II |

| Rated Capacity (KVA) |

100 |

| Input Voltage |

Three Phases 380V 50Hz |

| Input Current (A) |

263 |

| Output No-load Voltage (V) |

6.3 |

| Rated Duty Cycle (%) |

50% |

| Max. Welding Thickness (mm) |

1.2+1.2 |

| Welding Speed |

0.8-3.2m/min |

| Electrode Stroke |

20mm |

| Flow of Cooling Water |

120L/h |

Key Features & Advantages:

- Dual-Function Welding Capability: Unique two-shaft design allows one machine to weld both standard straight pipe seams and complex elbow/neck seams, eliminating the need for multiple machines or manual rework.

- Application-Specific Curved Electrode Shaft: The custom-bent lower copper arm is engineered to follow the internal radius of pipe elbows, ensuring consistent electrode contact and weld quality along the entire curved joint.

- High-Capacity Square-Box Conduction System: Utilizes a robust square-box secondary circuit (standard for >75KVA machines) to deliver stable, high welding current (263A input) with minimal electrical loss and heating, crucial for 100KVA output.

- Optimized for Thin-Gauge Ductwork: Precision control via the KF-9 controller and adjustable parameters are fine-tuned for welding thin cold-rolled and stainless steel sheets (0.5–1.2mm), preventing burn-through and ensuring airtight seams.

- Versatile Diameter Range: Accommodates a wide range of pipe diameters from ∮80mm to ∮300mm, making it suitable for various smoke vent and exhaust duct applications.

- Proven FN Series Reliability: Built on the reliable FN Series platform, ensuring industrial durability and consistent performance in demanding workshop environments.

- Reduced Production Complexity: Consolidates two welding processes (straight seam and elbow seam) into one machine, streamlining workflow, reducing floor space, and lowering capital investment.

Workpiece:

Applications:

This specialized machine is designed exclusively for manufacturing and repairing:

Smoke Ventilation & Exhaust Systems: Welding longitudinal and elbow seams for kitchen hood ducts, industrial smoke vents, and fireplace flues.

HVAC Ducting: Fabrication of curved fittings, elbows, and transitions in heating, ventilation, and air conditioning ductwork.

Industrial Exhaust Pipes: Production of custom-shaped exhaust pipes for machinery, engines, and processing equipment.

Thin-Walled Cylindrical & Curved Components: Any application requiring an airtight circumferential seam on curved, thin-gauge metal sections.

Why Choose the FN-100II Customized Seam Welder?

- Solves a Specific Production Challenge: Directly addresses the difficulty of welding curved pipe seams with a purpose-built electrode system, improving quality and yield on elbow joints.

- Increases Production Flexibility: The interchangeable shaft system allows quick changeover between straight pipe and elbow welding, maximizing machine utilization.

- Ensures Welding Process Integrity: The square-box conduction system guarantees stable electrical performance at high power, essential for repeatable weld quality on thin materials.

- Delivers a Complete, Ready-to-Run Solution: Supplied with both curved and straight electrode assemblies, configured and tested for your specific workpiece range (∮80–300mm pipes, 0.5–1.2mm thickness).

- Built for Durability and Ease of Use: Combines the rugged FN Series construction with the straightforward operation of the KF-9 controller, ensuring reliable performance with minimal operator training.

For manufacturers of smoke vent pipes, HVAC ducting, or any application requiring high-quality circumferential welds on both straight and curved thin-walled sections, the FN-100II Customized Resistance Circular Seam Welding Machine provides a specialized, efficient, and reliable solution that standard machines cannot match.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!