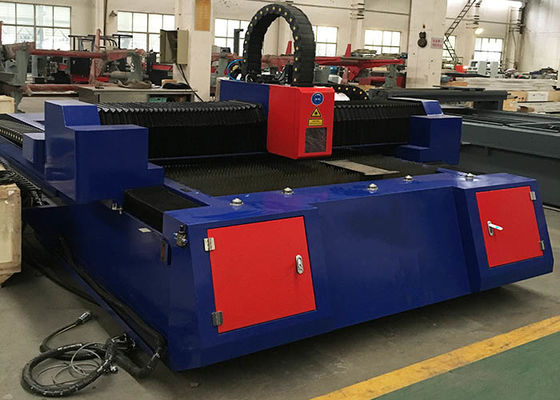

FL-3015-4000W CNC Fiber Laser Cutting Machine

The FL Series 4000W Fiber Laser Cutting System, built on our revolutionary monolithic bed architecture, is engineered to dominate the critical mid-thickness production range. Designed around a highly versatile 1500mm x 3000mm (approx. 5' x 10') work area, this machine is not just about raw power—it’s about delivering unmatched throughput, reliability, and cut quality on materials from thin-gauge sheet up to heavy plate. It represents the optimal balance of industrial capability and practical floor space, making professional-grade, high-speed laser cutting accessible for job shops, fabricators, and OEMs looking to scale their operations. This platform transforms complex part profiles into finished components with breathtaking speed and flawless precision.

Core Differentiators: Why the FL Series 4KW Stands Apart

-

Strategic Power for Optimal ROI: The 4KW laser source is scientifically calibrated to be the "sweet spot" for production. It delivers blistering speeds on thin to medium materials (1-10mm) while retaining robust cutting capacity up to 25mm carbon steel and 20mm stainless steel, maximizing your return on investment across the broadest range of common jobs.

-

1500x3000mm: The High-Efficiency Format: This work area is meticulously sized to handle full sheets from multiple global standard sizes with minimal waste, perfectly suited for nested cutting of multiple parts. It dramatically reduces material handling time and optimizes material yield compared to smaller beds, directly boosting shop floor productivity.

-

Dynamics-Optimized Motion System: Paired with the 4KW source is a high-dynamics drive system engineered for aggressive acceleration and deceleration. This ensures that the laser head hits its peak cutting speed faster and navigates complex contours more accurately, reducing cycle times on intricate parts—where other machines lose time, the PRO Series gains it.

-

Intelligent Gas & Process Management: Features an advanced, programmable assist gas system that auto-switches pressure and gas type based on material and thickness from the cutting database. This ensures optimal cut quality (dross-free, oxide-minimized) from the first part to the last, while conserving expensive high-purity gases.

-

Production-Ready Uptime Features: Includes integrated automatic nozzle cleaning and calibration (AFC), collision protection, and real-time monitoring of optics temperature and laser status. These features minimize operator intervention, prevent costly crashes, and ensure the machine spends more time cutting and less time in maintenance.

Fiber Laser Generator:

The machine can equip Raycus / IPG fiber laser generator, according customer demands.

Technical Parameters:

| Category |

Specification |

| Model |

FL-3015-4KW |

| Laser Power |

4000W IPG / Raycus / Max Photonics Fiber Laser (Configurable) |

| Effective Work Area |

1500 mm (X) x 3000 mm (Y) |

| Machine Construction |

Monolithic Welded Steel Frame with Integrated High-Strength Bed Plate |

| Positioning Accuracy |

±0.03 mm |

| Repeatability |

±0.02 mm |

| Maximum Travel Speed |

140 m/min |

| Maximum Acceleration |

1.5 G |

| Drive System |

High-Precision Servo Motors with Helical Rack & Pinion |

| Guideways |

Taiwan/Japan Brand High-Rigidity Linear Guides |

| Control System |

CYPCUT 8000 or PA 8000 Professional CNC System with 21" Touchscreen |

| Cutting Capacity (Max.) |

Carbon Steel: 25 mm

Stainless Steel: 20 mm

Aluminum: 16 mm

|

| Assist Gas |

Programmable System for O₂, N₂, Air (High-Pressure Nitrogen Option Available) |

| Automatic Features |

Auto Focus (AF), Auto Nozzle Change (ANC), Capacitive Height Sensor (Standard) |

| Chiller |

40HP High-Precision Industrial Dual-Circuit Water Chiller |

| Exhaust System |

Integrated High-Flow Ducting, Compatible with Central/Smoke Filter Systems |

| Power Requirements |

380V / 50Hz / 3-Phase, Approx. 55 kVA |

| Machine Dimensions (LxWxH) |

~ 5500 mm x 2600 mm x 2100 mm (Including Exhaust) |

| Net Weight |

Approx. 8000 kg |

Cutting Parameters:

| Material |

Thickness (mm) |

Cutting Speed (m/min) |

Assist Gas & Pressure (Bar) |

Notes |

| Carbon Steel |

1 |

35 – 45 |

O₂ (1.0 - 1.5) |

Very high speed, minimal dross. |

| |

3 |

12 – 15 |

O₂ (0.8 - 1.2) |

|

| |

6 |

4.5 – 5.5 |

O₂ (0.8 - 1.0) |

|

| |

10 |

2.2 – 2.8 |

O₂ (0.8 - 1.0) |

|

| |

15 |

1.3 – 1.7 |

O₂ (0.8 - 1.0) |

Good quality with O₂. |

| |

20 |

0.8 – 1.0 |

O₂ (0.8 - 1.0) |

Capable of clean cutting. |

| |

25 |

0.5 – 0.7 |

O₂ (1.0 - 1.2) |

Near maximum capacity, edge may be rougher. |

| Stainless Steel |

1 |

28 – 36 |

N₂ (14 - 18) |

High speed, bright, oxide-free edge. |

| |

3 |

8 – 10 |

N₂ (14 - 18) |

|

| |

6 |

3.5 – 4.5 |

N₂ (14 - 18) |

|

| |

10 |

1.5 – 2.0 |

N₂ (16 - 20) |

|

| |

15 |

0.8 – 1.2 |

N₂ (18 - 22) |

High pressure N₂ required for melt ejection. |

| |

20 |

0.4 – 0.6 |

N₂ (20 - 25) |

Near practical limit for high-quality cuts. |

| Aluminum |

1 |

25 – 35 |

N₂ (12 - 16) |

High reflectivity material, requires optimized parameters. |

| |

3 |

8 – 11 |

N₂ (14 - 18) |

|

| |

6 |

3.0 – 4.0 |

N₂ (16 - 20) |

|

| |

10 |

1.2 – 1.8 |

N₂ (18 - 22) |

|

| |

15 |

0.6 – 0.9 |

N₂ (20 - 25) |

Challenging, speed heavily dependent on alloy. |

| Brass / Copper |

1 |

18 – 25 |

N₂ (14 - 18) |

Extremely high reflectivity. Use anti-reflection coating or dedicated high-power laser head. |

| |

3 |

4.0 – 6.0 |

N₂ (16 - 20) |

|

| |

6 |

1.2 – 1.8 |

N₂ (18 - 22) |

Very slow compared to steel; high thermal conductivity. |

| Mild Steel (N₂) |

1 |

18 – 24 |

N₂ (14 - 18) |

For oxide-free, paintable edges. Slower than O₂ cutting. |

| |

3 |

5 – 7 |

N₂ (14 - 18) |

|

| |

6 |

2.0 – 2.8 |

N₂ (16 - 20) |

|

Questions:

1. Are you a trading company or factory?

--- We are factory occupying more than 100,000 m2, with excellent and professional technical team, 25 R&D personnel, professional after-sales team, and around 200 workers producing more than 1000 sets machines each year.

2. Does your company supply and build the machines to suit customer's needs and specifications?

--- Yes, we can custom-made the machine according to your requirements.

3. What is your advantages over your competitors' machine?

--- Our machines can be equipped with high configuration, and main components are from famous brands. We have strict quality control system, process technology system, technology innovate system.

4. Does the machine come with a guarantee?

--- We offer one year of warranty, during this time, if any parts broken, we will send a new one to customer free of charge, and we will also supply on-line the technical guidance for ever free.

5. Can I go to visit your factory?

--- Welcome to visit our factory to know our processing and technology power. And you will see different sample machine at our workshop.

6. How to get quicker quotation?

--- When you send us inquiry, please offer your requirement information:

• What kind of metal plate and the thickness?

• What’s the size of your workpiece?

These information is helpful for us to choose suitable equipment solution and price quickly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!