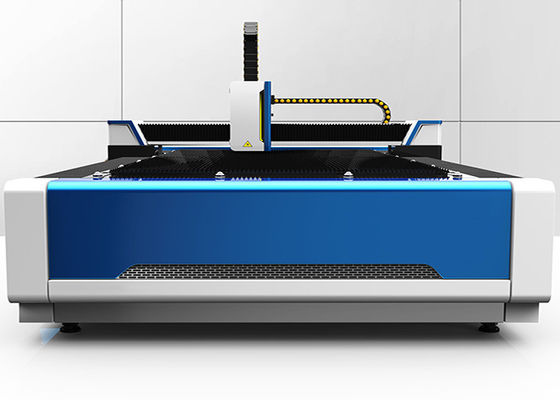

Economical Table Type CNC Fiber Laser Cutting Machine

Product Introduction:

The Table type Fiber Laser Cutting Machine Series represents a breakthrough in affordable, high-performance laser cutting technology. Designed for small to medium-sized workshops, manufacturing facilities, educational institutions, and prototyping labs, this series delivers industrial-grade cutting capabilities in a compact, cost-effective package. Spanning from 1500W to 12kW laser power options, these machines are engineered to handle a diverse range of materials with exceptional precision and efficiency.

Built with a rigid, thermally stable table type frame, the series combines the reliability of professional laser cutting systems with the accessibility of bench-top equipment. Whether you're processing thin sheet metal for intricate components or cutting thicker materials for industrial parts, this versatile machine series adapts to your production needs without compromising on cut quality or operational simplicity.

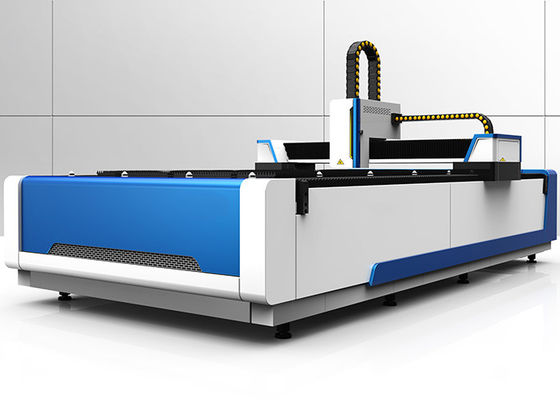

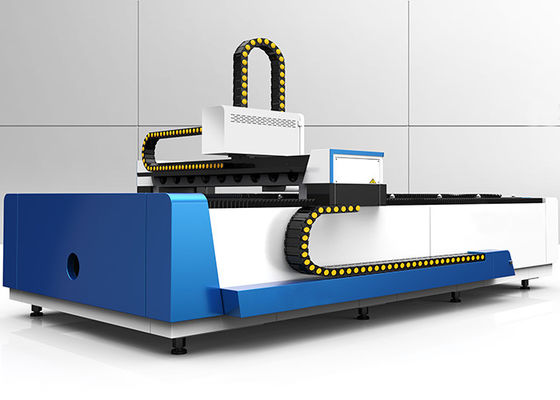

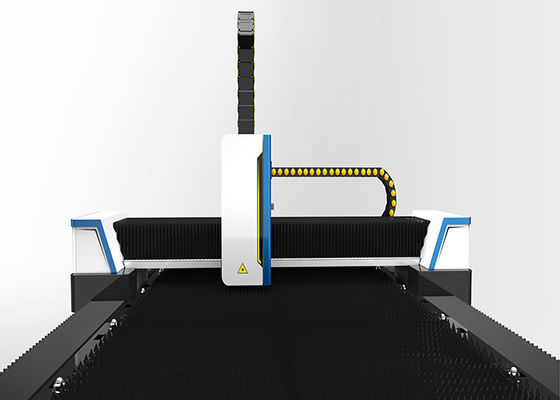

Product Structure:

Key Product Features:

1. Cost-Optimized Performance

• Affordable Entry Point: Achieve professional cutting results at a fraction of traditional laser system costs

• Low Operational Expenses: Energy-efficient fiber laser source with minimal maintenance requirements

• Reduced Consumable Costs: Long-life optical components and minimal gas consumption

2. Precision Engineering

• High-Accuracy Motion System: Precision ground ball screws and linear guides ensure repeatable positioning accuracy of ±0.02mm and positioning accuracy of ±0.03mm/m

• Advanced Control System: User-friendly CNC interface (Bodor/Bochu System) with intuitive software for seamless operation

• Automatic Focus Control: Motorized Z-axis maintains optimal focal distance for consistent cut quality

3. Versatile Material Processing

• Multi-Material Capability: Cut stainless steel, carbon steel, aluminum, copper, brass, and various alloys

• Adaptive Power Range: 1500W-12kW options balance cutting speed and material thickness capacity

• Intelligent Parameter Database: Pre-configured cutting parameters for common materials and thicknesses

4. Compact & Space-Efficient Design

• Table type Footprint: Requires minimal floor space while maintaining substantial working area

• Integrated Enclosure: Complete safety enclosure with viewing window and interlock system

• Modular Construction: Easy maintenance access and potential for future upgrades

5. Smart Operation & Safety

• Automatic Nozzle Changing: Optional system for uninterrupted processing of different material thicknesses

• Comprehensive Safety Features: Light curtains, emergency stops, fume extraction interface, and Class 1 laser safety enclosure

• Remote Monitoring Capability: Network connectivity for production monitoring and diagnostics

6. Enhanced Productivity Features

• High-Speed Processing: Rapid traverse speeds up to 120m/min (varies by power model) for reduced cycle times

• Intelligent Nesting Software: Maximize material utilization with automatic part nesting algorithms

• Quick Material Change System: Simplified material loading and clamping mechanism

Main Components:

Technical Parameters:

| Name |

1500W Model |

3000W Model |

6000W Model |

12000W Model |

| Laser Type |

IPG/RAYCUS Fiber Laser |

IPG/RAYCUS Fiber Laser |

IPG Fiber Laser |

IPG High-Power Fiber Laser |

| Laser Power |

1500W |

3000W |

6000W |

12000W |

| Wavelength |

1070nm |

1070nm |

1070nm |

1070nm |

| Beam Quality (M²) |

<1.2 |

<1.2 |

<1.2 |

<1.3 |

| Max Cutting Thickness (Mild Steel) |

8mm |

15mm |

25mm |

35mm |

| Max Cutting Thickness (Stainless Steel) |

6mm |

12mm |

20mm |

30mm |

| Max Cutting Thickness (Aluminum) |

5mm |

10mm |

16mm |

25mm |

| Positioning Accuracy |

±0.03mm/m |

±0.03mm/m |

±0.03mm/m |

±0.04mm/m |

| Repeat Positioning Accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

±0.025mm |

| Working Area (X×Y) |

1500×3000mm |

1500×3000mm |

2000×4000mm |

2000×4000mm |

| Max Traverse Speed |

60m/min |

80m/min |

100m/min |

120m/min |

| Drive System |

Servo Motors + Ball Screws |

Servo Motors + Ball Screws |

Servo Motors + Ball Screws |

Servo Motors + Gear Rack |

| Guide System |

Linear Guides |

Linear Guides |

Linear Guides |

Heavy-Duty Linear Guides |

| CNC Controller |

Bochu System |

| Cooling Capacity |

12kW Water Chiller |

18kW Water Chiller |

28kW Water Chiller |

45kW Water Chiller |

| Temperature Stability |

±1°C |

±1°C |

±1°C |

±0.5°C |

| Assist Gas Types |

Air, O₂, N₂ |

Air, O₂, N₂ |

O₂, N₂ |

O₂, N₂ |

| Max Gas Pressure |

1.6MPa |

1.6MPa |

2.0MPa |

2.5MPa |

| Gas Consumption (N₂) |

15-25m³/h |

20-35m³/h |

30-50m³/h |

50-80m³/h |

| Machine Dimensions (L×W×H) |

3200×2200×2000mm |

3200×2200×2000mm |

4500×2800×2200mm |

4500×2800×2200mm |

| Machine Weight |

1800kg |

2000kg |

3200kg |

3800kg |

| Power Requirements |

380V/3PH/32A |

380V/3PH/45A |

380V/3PH/65A |

380V/3PH/100A |

| Power Consumption |

8-12kVA |

12-18kVA |

20-30kVA |

35-50kVA |

| Working Environment |

Temperature: 5°C-35°C; Humidity: 30%-80% (No Condensation); Altitude: ≤1000m |

Additional Performance Data:

| Material Type |

Thickness |

1500W Cutting Speed |

3000W Cutting Speed |

6000W Cutting Speed |

12000W Cutting Speed |

| Mild Steel (with O₂) |

1mm |

18m/min |

25m/min |

35m/min |

50m/min |

| 3mm |

4.5m/min |

8m/min |

12m/min |

20m/min |

| 6mm |

1.2m/min |

3m/min |

5m/min |

9m/min |

| Stainless Steel (with N₂) |

1mm |

15m/min |

22m/min |

30m/min |

45m/min |

| 3mm |

3m/min |

6m/min |

10m/min |

16m/min |

| 6mm |

0.8m/min |

2m/min |

4m/min |

7m/min |

| Aluminum (with N₂) |

1mm |

12m/min |

18m/min |

25m/min |

40m/min |

| 3mm |

2.5m/min |

5m/min |

8m/min |

14m/min |

| 6mm |

0.6m/min |

1.5m/min |

3m/min |

6m/min |

Note: All specifications are subject to change based on technological improvements. Actual performance may vary depending on material quality, assist gas purity, and operating conditions. Contact our technical team for specific application recommendations and custom configuration options.

Cutting Samples:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!