Automatic Stainless Steel Metal Fiber Laser Pipe Tube Cutting Machine

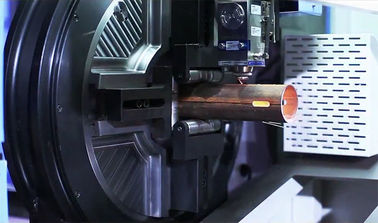

The laser cutting machine is fiber laser type designed for efficient processing of pipes of carbon steel,stainless steel,aluminum,brass and many more. Available in different workstations sizes with several power options, these laser cutting systems provide high-quality results at maximum speed.

Cutting range 6000mm dia ,200mm round pipe, 150 dia Square pipes, suitable for of stainless steel tube, round tube, square tube and oval tube,make cutting become simple.

It has heavy and strong structure, high performance and can works stably more than 10 years without problem.

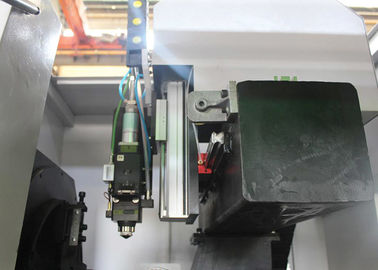

The whole fiber laser cutting machine for metal consist of machine This system consist of machine tool, motion parts, electrical equipment control parts, and other assist parts. Via control system to operation three axis motion parts, so it can drive to fiber laser cutting head achieve a stable, accurate, and high speed moving; X and Y axis adopt by imported with original packaging high quality and precision HIWIN linear guide rail, working table adopt by square pipe to welding the overall machine, stress relief annealing treat, the max load-bearing of mesa could get 500 KG, it also has universal ball bearing, machine external set up peripheral clamping device, use full enclosed dust proof device, photoelectric sensor, and other precise positioning parts to ensure accuracy of the transmission.

Advantages:

1). Great Performance: with excellent path quality, Identical cutting quality on any cutting point is realized through fiber transmission.

2). High Cutting Speed: The rapid cutting speed is two times higher than that of CO2 laser machine. Its use-cost is very low.

3). Low Cost: Save energy and Environmentally friendly because of low gas Consumption: Laser cutting does not make any gas because of the specific cutting technology on steel plate. power consumption is reduced by 20%-30% compared with CO2 laser.

4). High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have 3 times photoelectric conversion efficiency.

5). Stable Running: adopt top world import fiber laser generator, stable performance, key parts can reach 100,000 hours; Machine bed treated by 650℃ heat treatment ensure its stability and smoothness.

6). Maintenance-free: The machine is maintenance-free, there is almost no any parts need to change after long term use.

7). Easy operations: fiber line transmission, no adjustment of optical path.

Features:

1.The whole structure is welded, stable performance, to ensure the stable operation.

2. With 650 degree high temperature heat treatment working bed and a large milling machine high precision machining to ensure the stability and smoothness of the working bed.

3. Operation system, easy control system, easy to learn and operating.

4. High quality, high efficiency fiber laser generator, low processing cost, saving help energy conservation and environmental protection.

5. Automatic chuck the front and bottom, easy to feeding, designed for saving material.

6. Equipped with servo system from Japan, gear rack movement structure using, to ensure the high speed, high precision, high reliability.

7. New beautiful designed, fully enclosed protective cover.

Applicable Industry:

Fiber Laser Cutting Machines are widely used in manufacturing Sports Equipment, Aviation & Spaceflight parts, Ships, Automobile, Elevator, Subway parts, Electronics, Electrical Appliances, Precision Components, Machinery, Household appliances, Adornment, Advertising, etc. various high precision components processing industries.

Technical Parameters:

| Technical Parameter | 1.5KW | 3KW | 6KW | 12KW | 20KW | 30KW |

| Laser Power | 1500W | 3000W | 6000W | 12000W | 20000W | 30000W |

| Laser Wavelength | 1070nm | 1070nm | 1070nm | 1070nm | 1070nm | 1070nm |

| Laser Source Type | Fiber Laser | Fiber Laser | Fiber Laser | Fiber Laser | Fiber Laser | Fiber Laser |

| Max. Processing Length | ≤6500mm | ≤12000mm | ≤15000mm | ≤20000mm | ≤20000mm | ≥20000mm |

| Round Tube Diameter Range | 20-350mm | 20-500mm | 20-600mm | 20-800mm | 20-1000mm | 20-1200mm |

| Square Tube Side Range | ≤300mm | ≤450mm | ≤600mm | ≤800mm | ≤1000mm | ≤1200mm |

| Rectangular Tube Secti on Range | ≤300×250mm | ≤500×400mm | ≤600×500mm | ≤800×600mm | ≤1000×800mm | ≤1200×1000mm |

| Max. Carbon Steel Cutting Thickness | 16mm | 25mm | 35mm | 50mm | 70mm | 90mm |

| Max. Stainless Steel Cutting Thickness | 12mm | 20mm | 30mm | 40mm | 55mm | 70mm |

| Max. Aluminum Alloy Cutting Thickness | 10mm | 16mm | 22mm | 30mm | 40mm | 55mm |

| Kerf Width | 0.15-0.25mm | 0.2-0.3mm | 0.25-0.4mm | 0.3-0.5mm | 0.4-0.7mm | 0.5-0.9mm |

| Positioning Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repeat Positioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Spindle Speed Range | 0-120 rpm | 0-100 rpm | 0-80 rpm | 0-60 rpm | 0-50 rpm | 0-40 rpm |

| Chuck Clamping Method | Pneumatic/Hydraulic | Pneumatic/Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Control System | Cypcut/Siemens/Beckhoff |

| Power Supply Requirement | 380V / 50Hz / 3-Phase |

| Total Machine Power Consumption | ≈25 kVA | ≈45 kVA | ≈80 kVA | ≈150 kVA | ≈220 kVA | ≈320 kVA |

| Cooling Method | Water Cooling |

| Assist Gas Requirement | O₂ / N₂ / Compressed Air |

| Number of CNC Axes | 4 Axes (X, Y, Z, C) | 5 Axes (X, Y, Z, C, A) | 5 Axes (X, Y, Z, C, A) | 6 Axes (Multi-axis) | 6 Axes (Multi-axis) | 6 Axes (Multi-axis) |

| Supported Tube Profiles | Round, Square, Rectangular Tubes; Angle Steel, Channel Steel, I-Beam, Special Profiles |

Cutting Samples:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!