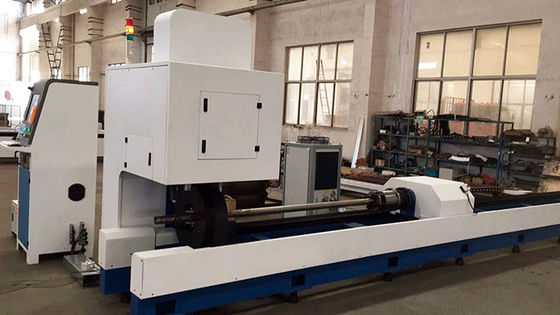

FL-T-6000W Tube Fiber Laser Cutting Machine

FL-T-6000W tube laser fiber cutting machine germany quality is professional tube cutting fiber laser machine, suitable for all kinds of stainless tube, round tube, square tube and oval tube. Improve the quality of tube cutting products, make cutting become simple.

Performance Features:

High-Power Precision Cutting

Excellent for batch processing of thick-walled tubes and large structural components with high efficiency and precision

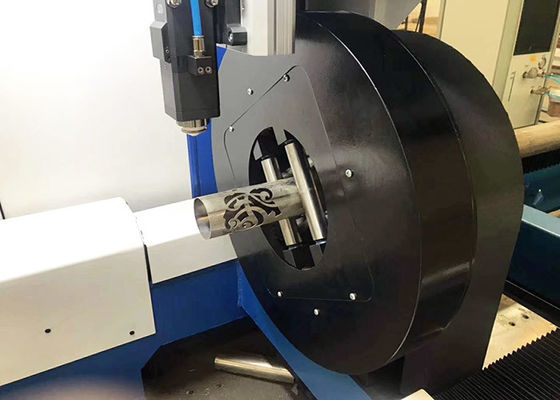

5-Axis Simultaneous Control

Capable of complex 3D hole cutting, compound angle bevel cutting, and 3D contour processing without repositioning

Intelligent Process Optimization

Built-in cutting parameter database for various materials and thicknesses with automatic optimization functions

Heavy-Duty Construction

Cast iron bed with reinforced structure and heavy-duty linear guides ensure vibration-free operation and long-term stability

Advanced Automation Integration

Ready for integration with automated material handling systems, robotic loading/unloading, and factory management systems

Main Components:

Technical Parameters:

| Parameter Category |

Technical Specifications |

| Laser Power |

6000W |

| Laser Wavelength |

1070nm |

| Laser Source Type |

Fiber Laser |

| Max. Processing Length |

≤15000mm |

| Round Tube Diameter Range |

20-600mm |

| Square Tube Side Range |

≤600mm |

| Rectangular Tube Section Range |

≤600×500mm |

| Max. Carbon Steel Cutting Thickness |

35mm |

| Max. Stainless Steel Cutting Thickness |

30mm |

| Max. Aluminum Alloy Cutting Thickness |

22mm |

| Kerf Width |

0.25-0.4mm |

| Positioning Accuracy |

±0.03mm/m |

| Repeat Positioning Accuracy |

±0.02mm |

| Spindle Speed Range |

0-80 rpm |

| Chuck Clamping Method |

Hydraulic |

| Control System |

Bystronic/Siemens/Beckhoff |

| Power Supply Requirement |

380V / 50Hz / 3-Phase |

| Total Machine Power Consumption |

≈80 kVA |

| Cooling Method |

Water Cooling |

| Assist Gas Requirement |

O₂ / N₂ / Compressed Air |

| Number of CNC Axes |

5 Axes (X, Y, Z, C, A) |

| Supported Tube Profiles |

Round, Square, Rectangular Tubes; Angle Steel, Channel Steel, I-Beam, Special Profiles |

| Standard Features |

Auto Loading/Unloading, Vision Centering System, Bevel Cutting (0-45°), Online Marking, High-Efficiency Dust Removal |

| Optional Features |

Offline Programming Software, Remote Monitoring & Diagnostics, Intelligent Process Database, Adaptive Cutting System |

| Machine Dimensions (Approx.) |

L12000×W3500×H2500mm |

| Machine Weight (Approx.) |

12-15 tons |

| Floor Space Requirement |

15000×4000mm (including material handling area) |

| Operating Temperature Range |

10-35°C |

| Relative Humidity Range |

≤80% (non-condensing) |

| Cutting Speed Range |

0.5-20 m/min (depending on material and thickness) |

| Acceleration |

X/Y Axis: 1.0 G; C Axis: 2.0 rad/s² |

| Bevel Cutting Range |

0-45° (standard), up to 60° (optional) |

| Maximum Tube Weight (Single Piece) |

300 kg |

| Programming Software |

Tube cutting specialized CAD/CAM software with 3D simulation |

| Safety Features |

Laser safety enclosure (Class 1), Emergency stop buttons, Light curtains, Gas leak detection |

| Maintenance Interval |

2000 operating hours (routine maintenance), 8000 hours (major maintenance) |

| Warranty Period |

24 months (laser source: 18 months) |

Material Cutting Performance (Typical Values):

| Material |

Thickness |

Cutting Speed |

Assist Gas |

Surface Quality |

| Carbon Steel (Q235) |

20mm |

2.5-3.0 m/min |

O₂ |

Smooth, minimal dross |

| Carbon Steel (Q235) |

35mm |

0.8-1.2 m/min |

O₂ |

Good, slight slag |

| Stainless Steel (304) |

20mm |

1.5-2.0 m/min |

N₂ |

Bright, oxidation-free |

| Stainless Steel (304) |

30mm |

0.6-1.0 m/min |

N₂ |

Good, minimal heat effect |

| Aluminum (6061) |

15mm |

2.0-2.5 m/min |

N₂ |

Clean, minimal burr |

| Aluminum (6061) |

22mm |

1.0-1.5 m/min |

N₂ |

Acceptable, some roughness |

Typical Applications:

- Engineering machinery and construction equipment structural parts

- Building steel structures and architectural frameworks

- Oil and gas pipeline components and fittings

- Heavy vehicle chassis and frame components

- Large-scale conveying system frameworks

- Industrial machinery and equipment fabrication

- Shipbuilding and marine structural components

FAQ:

Q: I know nothing about the laser cutting machine, what kind of machine I should choose?

A: Just tell us what you want to cut by this machine, the materials, size and thickness. Then we will send you a perfect solutions and suggestions.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.

Q: What’s the package?

A: We have 3 layers package. For the outside, we adopt wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by thickening plastic bag for waterproof.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. So please don’t worry, you will receive the parcel in good condition.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!