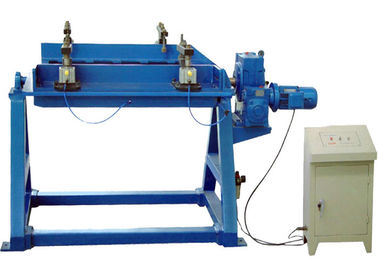

GZ12 Vertical Diaphragm Assembly Machine for Box Beam Production Line

This machine is the special equipment to assemble and weld the middle clapboards in Box-beam.

It adopts the cylinder compacting to determine the position when assembling, and then weld them by spot.

After one face welding finished, turn over the rotation work table for 180 degree by motor.

After welding another face, turn the work table to the horizontal level, loose the cylinder and unload the workpiece.

It can ensure the accurate positioning of box-beam baffle assembly and prevent the box-beam deformation during welding.

Technical Parameters:

| Working table overturning angle |

±180° |

| Working table load capacity |

1500 kg |

| Workpiece size |

300~1200 mm |

| Clapboard thickness |

20-80 mm |

| Overturning speed |

1.5r/min |

| Motor power |

0.75 kW |

Questions:

1. Are you a trading company or factory?

--- We are factory occupying more than 100,000 m2, with excellent and professional technical team, 25 R&D personnel, professional after-sales team, and around 200 workers producing more than 1000 sets machines each year.

2. Does your company supply and build the machines to suit customer's needs and specifications?

--- Yes, we can custom-made the machine according to your requirements.

3. What is your advantages over your competitors' machine?

--- Our machines can be equipped with high configuration, and main components are from famous brands. We have strict quality control system, process technology system, technology innovate system.

4. Does the machine come with a guarantee?

--- We offer one year of warranty, during this time, if any parts broken, we will send a new one to customer free of charge, and we will also supply on-line the technical guidance for ever free.

5. Can I go to visit your factory?

--- Welcome to visit our factory to know our processing and technology power. And you will see different sample machine at our workshop.

6. How to get quicker quotation?

--- When you send us inquiry, please offer your requirement information:

• What's the material of your Box beam?

• What's the min and max thickness of box beam plate?

• What's the min and max box beam section width?

• What's the min and max box beam section length?

• What’s the length of your box beam?

These information is helpful for us to choose suitable equipment solution and price quickly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!